Introduction to DOT Push-in Fittings

What are Push-in Fittings?

Push-in fittings are a specialized type of connector widely used in pneumatic systems, allowing for quick and secure connections between air tubing and various pneumatic components. These fittings are specifically designed to offer an efficient, leak-free connection without the need for threading, tools, or complicated procedures, making them a time-saving solution for industrial environments. The simplicity of a push-in design means that the fitting securely locks into place with just a simple push, providing a stable connection that can withstand air pressure, temperature variations, and environmental factors.

The ease of installation and the reliability of push-in fittings have made them indispensable in a variety of industries, from manufacturing to automotive systems. The connection they provide is incredibly tight and reliable, ensuring consistent performance without the need for frequent maintenance or repairs.

How Do Push-in Fittings Work?

Push-in fittings work by engaging a tube into the fitting. The internal mechanism automatically locks the tube in place, forming a tight seal that prevents any leakage, even under high pressure. These fittings often incorporate a spring-loaded mechanism or clamps to securely hold the tube in position and ensure that it remains firmly connected, even when subjected to vibrations or external forces.

The process is simple:

Push the tubing into the fitting.

The internal mechanism automatically locks the tube in place, ensuring a secure, leak-free connection.

The fitting maintains its grip on the tube, ensuring long-term performance and reliability.

The ease of this design not only reduces installation time but also allows for quick modifications to the pneumatic system when necessary, such as switching out tubes or changing configurations.

Why Push-in Fittings? Benefits of Using Push-in Fittings

Push-in fittings provide several advantages over traditional threaded fittings and other types of connectors. Their design not only simplifies the installation process but also offers superior functionality. Some key benefits include:

Time Efficiency:

One of the most significant benefits of push-in fittings is the time-saving installation process. No tools are required to install or remove the fittings, which significantly reduces the time spent during setup or reconfiguration of systems.

Leak-Free Connections:

With a built-in sealing mechanism, push-in fittings create tight, leak-proof connections. This is particularly crucial in high-pressure systems, where even a small leak can result in system failure or loss of pressure.

Versatility:

Push-in fittings can be used across a wide range of applications, from low-pressure to high-pressure systems. They are adaptable to different tube materials, such as nylon, polyurethane, and polyethylene, making them ideal for diverse industrial setups.

Durability:

These fittings are built to withstand harsh conditions. Their robust construction allows them to remain functional in environments with extreme temperatures or exposure to moisture, chemicals, or oil.

Ease of Maintenance:

The design of push-in fittings ensures that they require minimal maintenance. Since they are self-locking, there are no complex components that wear out over time, making them highly durable and reliable.

Compact and Lightweight:

Push-in fittings are designed to be compact, which means they do not take up much space in pneumatic setups. Their small footprint makes them especially useful in applications where space is at a premium.

Applications of Push-in Fittings

Push-in fittings are used extensively in various industries. Some of the most common applications include:

Automotive Industry:

Used in vehicle air brake systems, where high performance and reliability are crucial. The ease of installation in tight spaces makes push-in fittings ideal for automotive systems.

Manufacturing:

In automated production lines, push-in fittings are used to connect pneumatic tools and machinery. Their fast installation allows for rapid adjustments and minimizes downtime in production environments.

Medical and Healthcare Equipment:

Pneumatic systems are often used in medical devices for controlled airflow. Push-in fittings ensure that these systems operate reliably and efficiently.

Energy and Fire Protection:

Push-in fittings are used in systems within energy storage facilities and fire protection systems. These fittings can handle high temperatures and pressures, making them ideal for critical applications.

ISAIAH’s DOT Push-in Fittings: Precision and Reliability

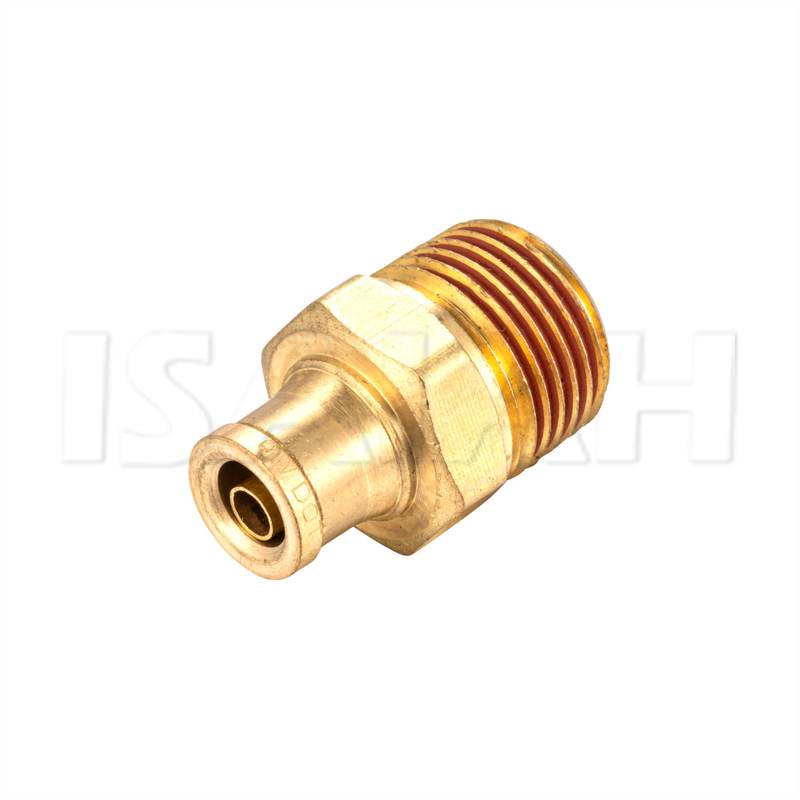

ISAIAH’s DOT Push-in Fittings Overview

ISAIAH’s DOT Push-in Fittings are engineered specifically to meet the stringent requirements of the Department of Transportation (DOT) standards. These fittings are designed to be used primarily in air brake systems for trailers, trucks, and other vehicles that require robust and reliable pneumatic connections. With over 20 years of expertise in the pneumatic industry, ISAIAH has developed these fittings to ensure easy installation, high durability, and leak-proof performance.

These fittings are essential for vehicles operating in heavy-duty environments, where they ensure smooth, continuous air flow for braking systems and other pneumatic functions. Their simplicity in installation combined with their high reliability makes them a trusted component in industries requiring precision and safety.

Key Features of ISAIAH DOT Push-in Fittings

DOT Compliance

Designed to meet DOT standards, these fittings are perfectly suited for air brake systems in trailers, trucks, and other vehicles. They provide a secure and leak-free connection in high-pressure pneumatic systems.

Easy One-Touch Installation

The push-in design allows for quick and tool-free installation, reducing downtime and increasing efficiency in vehicle maintenance.

Built for Durability

The embedded support sleeve inside the fitting ensures reliable performance even under extreme conditions. This added feature provides extra stability, ensuring the connection remains intact despite changes in pressure or temperature.

Leak-Proof Performance

The fittings feature an internal sealing mechanism designed to prevent leaks, making them ideal for systems where pressure consistency is crucial.

Compatibility

ISAIAH’s DOT Push-in fittings are compatible with SAE J844 type A&B nylon tubing, making them versatile and adaptable to various pneumatic setups.

Specifications of ISAIAH DOT Push-in Fittings

Fluid: Air

Operating Pressure: 0–1.7 MPa (250 psi)

Operating Temperature: -40°C to +90°C

Applicable Tubing: SAE J844 type A&B nylon tubing

These specifications ensure that the DOT Push-in fittings from ISAIAH are capable of handling demanding applications, ensuring long-lasting and reliable operation in high-performance environments.

Models in the DOT Push-in Fitting Series

ISAIAH offers a wide range of DOT Push-in fittings tailored to different needs and applications. Below are some of the models available:

ATE-DOT Push-in Fitting

The T-shaped fitting is perfect for splitting air lines and is designed for use in tight spaces where a branching connection is needed.

ATC-DOT Push-in Fitting

A straight connector, ideal for linear connections in air brake systems or other applications requiring direct, uninterrupted air flow.

ATL-DOT Push-in Fitting

This elbow connector is designed for 90-degree turns, providing flexibility in installations where space constraints or directional changes are necessary.

ATB-DOT Push-in Fitting

A T-connector designed for branching air lines, ensuring smooth distribution of air throughout the system.

ATU-DOT Push-in Fitting

A specialized fitting for connecting tubes in confined spaces, providing an efficient solution for installations with limited room for traditional connectors.

ATD-DOT Push-in Fitting

A T-connector fitting for air brake systems, designed for branching air lines efficiently and securely.

These models are crafted with precision to provide seamless integration into your pneumatic systems, whether for heavy-duty vehicles or industrial machinery.

Company Overview: ISAIAH Pneumatic

ISAIAH Pneumatic is a globally recognized leader in pneumatic components, with over 20 years of experience in manufacturing top-quality air fittings. Specializing in products like clean fittings, chemical fittings, flame-retardant fittings, and hydraulic hose fittings, ISAIAH has built a reputation for providing innovative solutions that ensure safety, reliability, and durability.

Our products are used in a variety of industries, including automotive, energy, and fire protection, and are known for their high performance and low maintenance requirements. With a focus on customer satisfaction, we offer a wide range of pneumatic solutions to meet the diverse needs of industries worldwide.

FAQs

1. How do DOT Push-in fittings ensure a secure seal?

DOT Push-in fittings use an internal locking mechanism that securely holds the tube in place. The internal seals provide a leak-proof connection, ensuring a tight seal under pressure.

2. What makes ISAIAH’s DOT Push-in fittings stand out from others?

ISAIAH’s DOT Push-in fittings are designed to meet DOT standards, ensuring high reliability in air brake systems. The one-touch installation and embedded support sleeve enhance their durability and ease of use.

3. What industries use DOT Push-in fittings?

DOT Push-in fittings are primarily used in the automotive industry, especially for air brake systems in trucks and trailers. They are also used in energy storage and fire protection systems.

4. How do I install DOT Push-in fittings?

Installation is simple: push the tube into the fitting until it locks securely into place. No tools are required, making installation quick and easy.

5. What is the maximum operating pressure for DOT Push-in fittings?

ISAIAH DOT Push-in fittings can handle an operating pressure of up to 1.7 MPa (250 psi), making them suitable for a wide range of pneumatic applications.