When electrical safety, compliance, and operational reliability are on the line, every small component matters. A Flame Retardant Fitting can determine whether a system contains a fire risk or allows it to spread unchecked. For procurement engineers, contractors, and plant managers, the decision isn’t just about price—it’s about preventing costly downtime and ensuring safety. This article explains what a Flame Retardant Fitting is, its common applications, how to choose the right one, pitfalls to avoid, and a buyer’s checklist. Zhejiang Isaiah Industrial Co.,Ltd provides high-quality solutions designed to help industries meet strict safety standards worldwide.

What exactly is a Flame Retardant Fitting?

Plain-language definition

A Flame Retardant Fitting is a specially designed connector, gland, or component that prevents flames from propagating through cable or pipe entry points, while also sealing the system against fire-related risks. In essence, it acts as both a protective barrier and a safety lock within electrical and mechanical installations.

Common types and forms

These fittings are not one-size-fits-all. They are available in several forms depending on the system:

Cable glands used for armored or unarmored electrical cables.

Pipe fittings designed for sprinkler or suppression systems.

Barrier fittings that include flame-resistant compounds to block ignition paths.

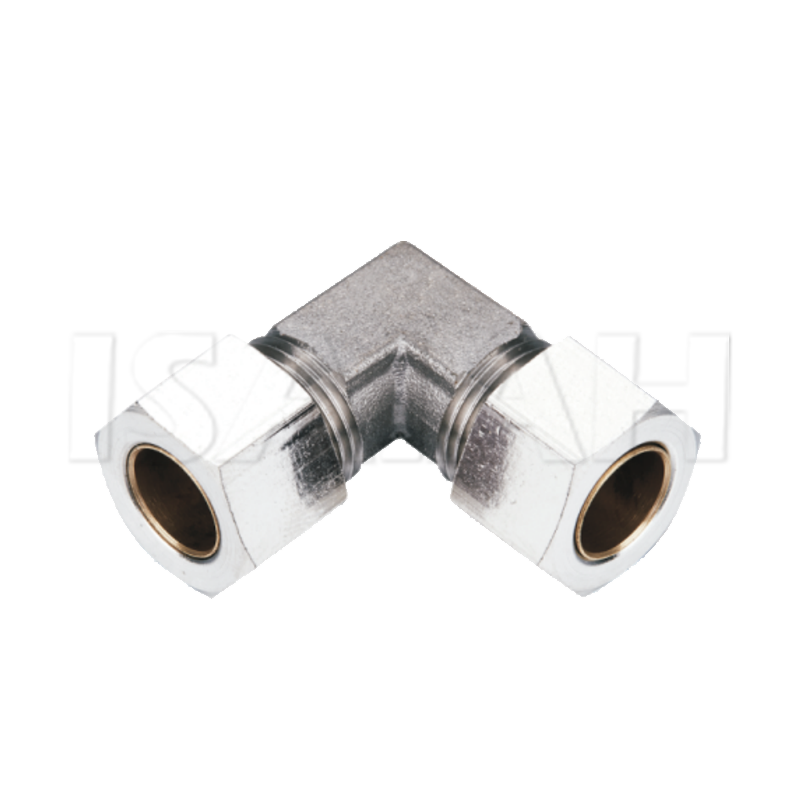

Transition fittings that connect different materials while maintaining flame resistance.

Materials and basic science

The effectiveness of a Flame Retardant Fitting depends heavily on material choice. Stainless steel provides high tensile strength and corrosion resistance, aluminum offers lightweight durability, while flame-resistant polymers bring insulation and thermal stability. These materials ensure fittings retain integrity under extreme heat, mechanical stress, or corrosive conditions—crucial for both safety and longevity. For many operators, selecting the correct alloy or polymer blend can mean the difference between passing and failing a regulatory inspection.

Where are Flame Retardant Fittings used and which risks do they reduce?

Typical industries and applications

You will often find these fittings in high-risk environments:

Oil and gas refineries and offshore platforms.

Chemical plants with flammable atmospheres.

Data centers requiring secure electrical cabling.

Fire suppression and sprinkler system pipework.

Hazardous-area electrical installations in mining or power generation.

Transportation hubs such as airports and subway systems.

What can go wrong without them

Without proper flame-retardant or flameproof cable glands, fire can travel along cable entries, causing catastrophic equipment failure. Unsealed fittings may allow flames to breach containment barriers, while weak materials could deform under heat, creating system-wide vulnerabilities. In industrial disasters, investigations often trace the root cause back to overlooked components such as poorly specified fittings.

How choice depends on environment

The right fitting varies by site conditions. Temperature extremes, explosive atmospheres, high humidity, or constant vibration all dictate specific material and certification needs. For example, offshore drilling requires saltwater-resistant stainless steel, while indoor data centers may prioritize polymer options that balance insulation with cost efficiency.

How to choose the right Flame Retardant Fitting

Match the standard and certification first

Before considering materials or size, confirm compliance with international codes. Standards such as IEC 60079 cover flameproof cable glands, ensuring products meet stringent testing. Certification is often required for insurance, audits, and legal operation—making it non-negotiable for safety managers and engineers. Always ask for proof of certification, not just marketing claims.

Material and mechanical requirements

Evaluate the fitting’s temperature range, tensile strength, and corrosion resistance. Stainless steel is ideal for marine or chemical exposure, while brass and polymer options may suit lower-risk environments. Durability ensures lifecycle savings even when upfront cost is higher. Choosing the wrong material often results in premature replacement and hidden maintenance expenses.

Cable or pipe compatibility and sealing

Not every fitting matches every cable. Consider conductor arrangement, insulation type, and whether armored or unarmored. Barrier glands with compound sealing are critical where explosive atmospheres exist. Equally, IP-rated sealing helps ensure dust- and water-resistance in harsh outdoor settings. Compatibility issues are one of the most common reasons for field rework and delays.

Installation and supplier support

Even the best fitting can fail with improper installation. Look for suppliers who provide torque specifications, detailed datasheets, and clear documentation. Test certificates and support in selecting the right gland type reduce the chance of error. Zhejiang Isaiah Industrial Co.,Ltd, for instance, supplies full technical support and certifications with its flame-retardant product line, helping contractors avoid costly mistakes.

Installation, inspection and common mistakes to avoid

Quick install checklist

Prepare cables correctly before fitting.

Apply compound or bedding where required.

Tighten glands to manufacturer torque specifications.

Confirm sealing integrity after installation.

Verify markings for certification before energizing the system.

Routine inspection and maintenance tips

Inspection intervals depend on environment, but most industrial facilities should review fittings annually. Signs of degradation include corrosion, cracks, or loose seals. Replacement should be scheduled immediately if safety performance is compromised. In some critical industries, such as petrochemical plants, quarterly inspections are recommended.

Three common pitfalls

Using a non-barrier gland where a barrier is required.

Selecting the wrong fitting size for the cable type.

Under- or over-torquing during installation, causing leaks or seal failure.

Cost vs. safety: evaluating ROI and specification trade-offs

Upfront cost vs lifecycle cost

While cheaper fittings exist, their limited durability can lead to costly downtime, repairs, or insurance penalties. Higher-grade Flame Retardant Fittings often pay for themselves through reduced failure rates and longer service life. A single avoided fire incident can justify the premium cost many times over.

How to justify to procurement or stakeholders

Arguments are straightforward: certified fittings prevent flame spread, lower insurance risks, reduce repair costs, and ensure compliance audits are passed without delay. They protect not only equipment but also workforce safety. Procurement teams often respond well to lifecycle cost comparisons that show measurable savings over a 5–10 year period.

When a basic fitting is acceptable and when it isn’t

In low-risk environments—such as indoor commercial wiring with minimal fire hazard—basic fittings may be sufficient. However, in hazardous or regulated industries, higher-spec flame-retardant solutions are the only responsible choice. Cutting corners in these settings is not just risky, but potentially unlawful.

FAQ

Is a flame retardant fitting the same as a flameproof gland?

Not always—flameproof glands are designed for explosive atmospheres, while flame retardant fittings broadly resist flame propagation.

Do fittings need re-certification?

The fitting itself does not, but systems may require recertification after modifications.

Can I retrofit an old installation with flame retardant fittings?

Yes, as long as the fittings match cable size and meet current certification standards.

Are polymer fittings as safe as metal ones?

In certain applications, yes, but polymers generally have lower mechanical strength compared to stainless steel or brass.

How long do flame retardant fittings last?

With proper material choice and routine inspection, service life can extend for many years.

What if my fitting doesn’t carry IEC certification?

It may not be legally accepted in regulated environments, risking both compliance and insurance coverage.

Conclusion

Selecting the right Flame Retardant Fitting is not just a technical detail—it is a key decision that reduces safety risks, ensures regulatory compliance, and avoids costly downtime. Zhejiang Isaiah Industrial Co.,Ltd provides certified, durable solutions to help industries maintain operational reliability while meeting international standards. For specifications, datasheets, or tailored support, contact us today.