In today’s industrial landscape, energy efficiency is more than a trend—it's a necessity. As manufacturers aim to reduce operational costs and meet environmental standards, optimizing the performance of pneumatic systems becomes critical. Among the many components that contribute to efficient air usage, the quick exhaust valve plays a key role.

By allowing faster exhaust of compressed air, quick exhaust valves improve actuator speed, reduce cycle times, and minimize energy waste. These benefits make them an essential part of energy-saving pneumatic designs.

Reducing Compressed Air Consumption

Compressed air is widely used in industrial applications, but it is also one of the most expensive utilities in a factory. This is primarily due to the high amount of electrical energy required to produce compressed air. Any inefficiencies in the system—such as leaks, slow exhaust, or unnecessary back pressure—can lead to wasted energy and increased operating costs. Implementing efficient components like a quick exhaust valve can significantly improve air usage and reduce overall energy consumption.

Faster Exhaust = Less Air for Return Strokes

In many pneumatic systems, cylinders perform a return stroke that typically requires less power than the working stroke. However, if the air used in the return stroke is not exhausted quickly and instead routed back through the directional control valve, it creates unnecessary delay. During this time, the compressor may continue to generate air to maintain pressure, even though the air isn’t being used effectively.

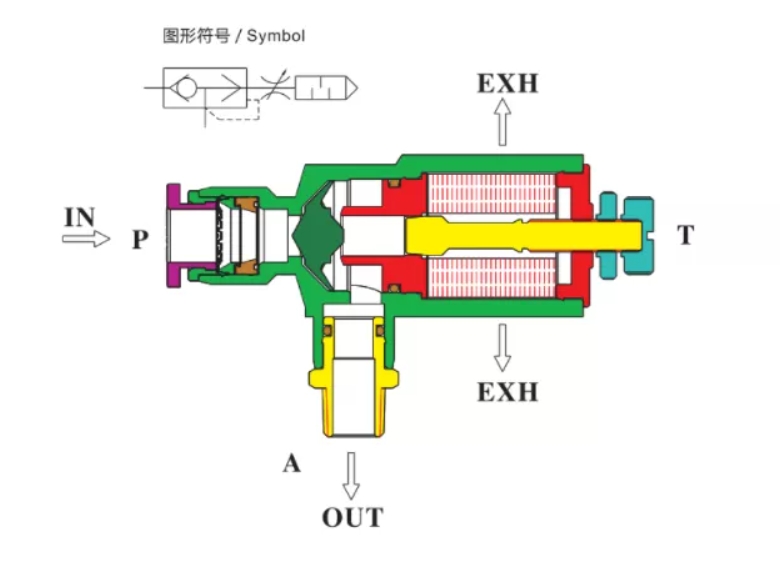

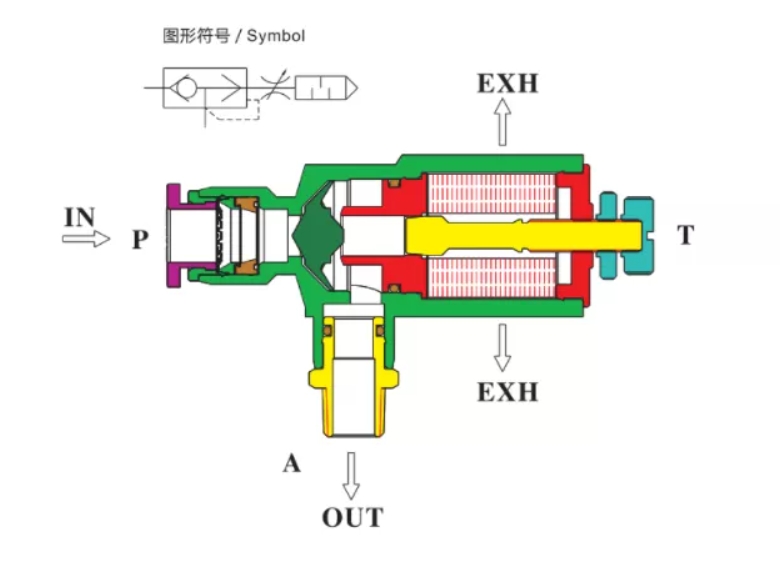

Installing a quick exhaust valve close to the actuator allows air to be expelled directly into the atmosphere, bypassing the longer route through the control valve. This results in a faster return stroke, shorter overall cycle times, and less compressed air required per operation. The outcome is improved efficiency and reduced strain on the compressor.

Lower Air Volume Requirements Per Cycle

Faster cylinder operation doesn’t just improve productivity—it also minimizes the amount of air required per cycle. Each time the cylinder completes a stroke, less air is used because it is expelled more efficiently and the system resets more quickly. This is especially beneficial in high-frequency applications such as:

By using a quick exhaust valve, manufacturers can achieve the same output with reduced air consumption, lowering energy costs and extending the lifespan of pneumatic components.

Minimizing Pressure Losses

Another common and often underestimated source of energy waste in pneumatic systems is pressure loss. These losses occur when compressed air travels through long tubing, multiple valves, or components with restrictive internal pathways before finally being exhausted. This resistance results in back pressure, which can reduce system responsiveness and force the compressor to work harder.

Direct Venting Avoids Back Pressure

Without a quick exhaust valve, spent air must return through the directional valve, which is not designed for efficient exhaust. This restrictive path leads to back pressure that slows actuator movement and causes inconsistent performance. By contrast, a quick exhaust valve installed close to the cylinder provides a direct and unrestricted path for the air to exit. This dramatically reduces resistance, improves flow, and maintains consistent pressure in the rest of the system.

Stable System Pressure Improves Compressor Efficiency

When pressure levels fluctuate due to slow exhaust or poor airflow, the compressor has to cycle more often to maintain the desired working pressure. Over time, this increases electricity usage and mechanical wear. A quick exhaust valve helps stabilize pressure by venting air quickly and reducing fluctuations. This allows the compressor to operate more efficiently, run fewer cycles, and consume less energy overall.

In conclusion, optimizing a pneumatic system with properly installed quick exhaust valves not only improves performance but also contributes to substantial energy savings and sustainability in industrial operations.

Shortening Cycle Times to Cut Energy Use

Time is money in manufacturing, and every second saved on machine cycles adds up to massive cost reductions over time. By enhancing the speed of pneumatic actuators, quick exhaust valves directly reduce the time it takes for machines to complete their tasks.

Faster Actuation = Fewer Operating Hours

In a production environment that runs thousands of cycles per shift, saving even 0.5 seconds per cycle can translate into hundreds of hours of machine runtime saved annually. With shorter cycles:

Machines complete jobs quicker

Operators spend less time per task

Energy-consuming components like compressors run for fewer total hours

Lower Total System Runtime Per Task

Faster actuator response also contributes to less wear on system components and reduced demand on the control system. When machines spend less time idling or waiting for cylinders to reset, energy usage is streamlined across the board.

Designing Circuits for Energy Recovery

Beyond minimizing waste, some advanced pneumatic systems aim to recover and reuse air, turning what would be waste into usable energy. Quick exhaust valves play a supporting role in such designs.

Use in Systems with Air Recovery or Reuse

In certain designs, exhausted air is collected through filters or routed into air-recovery tanks. A quick exhaust valve, placed strategically, allows:

Fast release of usable pressure

Immediate rerouting to an energy recovery system

Reduction of overall system pressure while retaining usable air

These setups are especially useful in:

Large-scale automotive production

Pneumatic systems in food and beverage industries

Energy-conscious factories striving for green certifications

Integration with Pressure Regulators and Smart Valves

Energy-efficient systems often pair quick exhaust valves with:

Pressure regulators: to maintain only the needed force

Smart valves: to monitor and adapt air usage

Sensors: to track cycle times and air consumption

This integration provides real-time optimization, allowing the system to respond intelligently to operational changes and reduce energy consumption further.

Case Studies and Comparative Analysis

To truly understand the impact of quick exhaust valves on energy usage, let’s examine a few real-world scenarios.

Case Study 1: Automotive Assembly Line

Before:

A car manufacturer used standard directional valves without quick exhaust valves. Cylinders had long return times, and the compressors were oversized to handle the slow exhaust.

After installing quick exhaust valves:

Cylinder retraction time dropped by 30%

Compressed air consumption decreased by 18%

Compressor cycle frequency was reduced by 25%

Case Study 2: Food Packaging Facility

Before:

High-speed packaging lines were experiencing inconsistent performance due to pressure drops and slow cylinder resets.

After implementing quick exhaust valves:

Line speed increased by 10%

Air consumption per cycle reduced by 12%

Energy costs related to air compression dropped by $15,000 annually

Case Study 3: Electronics Manufacturing

Small pneumatic arms used for delicate circuit placement benefited from precise exhaust control.

With quick exhaust valves:

Movement became smoother and more responsive

Less overshoot and bounce in actuator performance

Enhanced accuracy led to fewer defective units

These examples illustrate that whether the goal is speed, precision, or savings, the quick exhaust valve consistently contributes to higher efficiency and lower energy costs.

Conclusion

In modern manufacturing environments where every watt and second count, quick exhaust valves are unsung heroes. They’re compact, cost-effective, and incredibly powerful in optimizing the way pneumatic systems operate.

For any company aiming to improve sustainability and reduce operational expenses, incorporating quick exhaust valves into pneumatic system designs is a smart and simple step toward greener production.

Ready to upgrade your pneumatic system?

Consider working with reliable suppliers like INTELL PNEUMATIC TECHNOLOGY CO., LTD a trusted name in industrial pneumatic components. Their range of quick exhaust valves and expertise in air system efficiency can help you build faster, smarter, and more energy-conscious solutions.

Visit their official website or reach out to their technical team to explore how the right quick exhaust valve can drive your energy-saving goals forward.